Posted on OA: 26 Jun 2015

Image credit: NOAA

Image credit: NOAA

Pulling off the scenic highway that winds up the west coast and through the Puget Sound region, our tires crunch gravel as we enter the parking lot at Taylor Shellfish Farms in Shelton, Washington. It is difficult to imagine that this modest array of buildings is part of the largest shellfish growing operation in North America. The fifth generation family farm, established in 1889, is based here in Shelton, Washington, and over the years they have added facilities in Canada, California, and Hawaii.

Inside the processing plant, the smell of the ocean is vivid, fresh but not fishy.

The sound of machines – conveyor belts, forklifts, and refrigeration equipment – drowns out the voices of the workers packaging oysters, mussels, clams, and geoducks to be shipped to restaurants and stores around the globe.

Water runs over fresh oyster meat to remove sand and bits of shell. It washes across the cement floor between processing stations, and cascades in sheets off the edge of a stainless steel conveyor belt that ferries oysters to a line of men and women in yellow aprons who stand on milk crates as they sort and shuck the oysters.

The farm employs 550 people in the United States, 100 in Canada and 50 in Hong Kong, and is in the process of upgrading this processing plant from 20,000 to 80,000 square feet. Right now, things are going well for the business, but that hasn’t always been the case.

In 2006, things started to change: There were problems at the hatchery.

The hatchery is an hour up the road from Shelton in Quilcene, on the edge of the Olympic National Forest. Every Tuesday, employees extract oyster sperm and add it to a bucket filled with unfertilized eggs extracted from females. Within 20 minutes, the eggs are fertilized and moved to a series of tanks where they are monitored and fed a carefully calibrated slurry of algae while they grow from microscopic to the size of a grain of sand.

Each of the 48 large, egg-shaped tanks in the hatchery can hold upwards of 20 million developing larvae.

By 2006, the Taylor hatchery had been successfully producing oyster seed from larvae for 15 years. Unexplained mortalities occasionally occurred; when these failures happened, the company shut down operations, sterilized equipment and sent samples off to pathologists.

At first, they attributed the die off to Vibrio tubiashii, a naturally occurring bacteria that thrives in seawater and is fatal to shellfish, according to Bill Dewey, the farm’s director of communications and public policy. But an expensive filtration system installed to block out the bacteria failed to stop the oyster larvae from dying.

Shellfish farms represent more than $200 million for the collective economies of Alaska, Washington, Oregon, and California, so it was no surprise that the issue received a great deal of press coverage in the peak years of the crisis.

The scope of the problem led state and federal policy makers and government agencies, like the National Oceanic and Atmospheric Administration (NOAA), to coordinate a response.

Scientists from universities and NOAA believe the larvae deaths were caused by ocean acidification, a change in the chemistry of the ocean that affects carbonate ions, the building blocks for the shells of oysters and other calcifiers.

An oyster larva forms a shell in the first 48 hours of life. The shell will be 90 percent of its body weight, and is constructed before the feeding organ. In corrosive water, the oyster has to work so hard to build the shell that it burns up all of its energy before ever building a feeding organ. Without a way to feed, the oyster dies.

Ocean acidification is now known to be the result of ocean water absorbing roughly 30 percent of the excess anthropogenic, or human-generated, carbon dioxide (CO2) in our atmosphere.

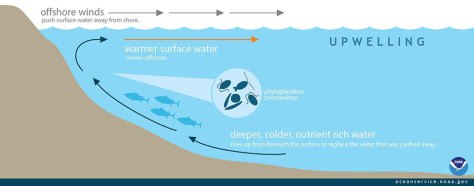

NOAA estimates that the corrosive water upwelling on the west coast is water that absorbed CO2 many years ago. Deep waters are high in CO2 to begin with, so when even more CO2 is added to the mix, upwelling brings highly corrosive water to the surface.

“Our system is naturally dynamic,” explains Dewey, who holds a degree in shellfish biology from the Univeristy of Washington. “Pre-industrial era water conditions would have been corrosive about 11 percent of the time. Because of the anthropogenic carbon, it’s over a third of the time now.”

If we completely stopped carbon emissions today, we would continue to see corrosive waters upwelling along the west coast for many, many years to come.

“That was probably the most sobering message,” says Dewey. No matter what, shellfish growers still had decades of acidification in front of them. “There’s nothing you can do about that. That’s already in the ocean and coming your way.”

For the short-term, Taylor farms came up with a relatively easy fix for the problem: a treatment system to return the water chemistry to favorable conditions within the controlled environment of the hatchery.

The head of larvae production at the hatchery, Becky Mabardy, shows off the facility’s ocean chemistry monitoring station housed in a Rubbermaid shed behind the hatchery where ocean water from the bay is pumped through a sensor that reads the pH and sends the information up to the hatchery.

When upwelling brings corrosive waters into the bay, the pH drops to about 7.5; the system responds by adding soda ash to the water before it circulates in the oyster tanks. This system allows the hatchery to keep pH levels at the ideal of 8.4.

The hatchery’s sensors are also connected to NOAA’s Integrated Ocean Observing System (IOOS), a network of telemetrized buoys that track a variety of ocean chemistry data.

The data can be used for predictive modeling and anticipating events.

The Pacific Northwest is connected to IOOS through a regional system called the Northwest Association of Networked Ocean Observing Systems (NANOOS).

Mabardy says, “At any given time it’s streamed online so you’re able to monitor the water chemistry all along the coast from Alaska to Washington, down the Oregon coast and into California, and up to Vancouver and British Columbia.”

While Taylor farms has successfully adapted to the current conditions, Dewey still sees reason for concern. In addition to oyster larvae, ocean acidification also impacts the food of our food, like the small swimming snails or pteropods, which are a dietary staple of pink salmon and other fish, mammals, and birds in high latitude regions.

This means there is potential for myriad problems throughout the food chain.

This doesn’t bode well for all the other calcifiers out there who don’t have the safe-harbor of a hatchery, Dewey says. “That’s roughly a third of the species in Puget Sound.”

While ocean acidification poses huge challenges, the news isn’t all dire.

With more than 30 years in the business, Dewey has seen enough environmental change to be optimistic about the ocean’s resilience. He tells the story of Oakland Bay in Shelton, currently a thriving and productive bay for Taylor Shellfish Farms.

The water quality in Oakland Bay got so bad in the 1960s that the bay was entirely dead. “People brought their boats there in the wintertime to kill the fouling on the hull of the boat,” Dewey says. “This is a bay that the shellfish industry left … It was dead. No barnacles, no crab, no nothing.”

At that time, the problem was more localized, what is referred to as point source pollution. Dewey says that historically, the point source on Oakland Bay and other area inlets were the pulp mills, whose effluent wrought havoc in the Puget Sound oyster industry.

The industry’s response to the pulp mills was to take them to court, and to influence policy and legislation. Since then, Oakland Bay has come back and is now one of the country’s largest shellfish-producing bays.

This success is encouraging as a reminder of ocean resilience.

Dewey cautions that point source pollution is still on the radar in new forms, such as microplastics, pharmaceuticals and personal care products, which contain unregulated chemicals that are “going through the sewage treatment plants and right out into the estuary.”

To Dewey, the obstacles to sustainable oceans today often cannot be traced to a single source like the pulp mills, and ocean acidification is the industry’s biggest problem in recent years.

Taylor’s long-term response to the issue has been to team up with local, national, and international organizations to fund monitoring and research, and develop technologies, to help the shellfish industry evolve.

“For our generation and our lifetime,” Dewey says, “our only hope is to monitor and do research to learn how to adapt.”

As the farm’s point man for this effort, Dewey maintains a busy daily itinerary that includes working with the Pacific Coast Shellfish Growers Association on regulations, permitting, and legislation. He engages with public policy efforts, attends conferences, gives talks, and works with lobbyists, scientists, and politicians to raise awareness and find solutions.

Despite Dewey’s international schedule of conferences and talks, the issue of ocean acidification is still a relatively new concept for the general public. He emphasizes the extent to which people care about this issue based on personal connections.

“Because people like to eat shellfish, there’s a direct link,” Dewey says, adding that jobs are another motivational factor. “But when you say this is also affecting pteropods,” he says, referring to those tiny swimming snails pink salmon eat, “well, that one step removed just doesn’t get people.”

As Dewey is getting into his truck to head to the airport for yet another trip to Washington D.C., he pauses to add some parting thoughts on ocean resilience. “(Oakland Bay is) a wonderful example of how resilient the ocean can be,” he says. But he cautions that ocean acidification is an unprecedented challenge.

“While I think the ocean can be resilient, history shows that the longer we wait, the longer it’s going to take to come back. It’s an experiment on a scale that the world has never seen before. So, we’re the canaries, so to speak.”

Jenny Woodman & Rachel Powers, Earthzine, 14 April 2015. Article.